|

|

|

| Seamer for cans |

|

Seamer for cans.

Approximate measurements:

Height 1600 mm x Width 900 mm x Length 900 mm. |

|

|

|

|

|

|

|

Main suggestions:

|

|

|

Beer bottling line, consisting of depalletizing, conveying, rinsing, filling, can seamer and level inspection.

Depalletizing machine for cans per hour.

In-line conveyor.

Mezzanine walkway.

Rotary filling machine for carbonated beer.

Wi... |

|

|

|

Brand: Levapack

Automatic seamer for aluminum, PET plastic and tin cans.

Manufacturer | model: LPE | Levapack.

Model: LPE - FHV50V.

With one head.

Stainless steel equipment.

Approximate capacity: 35 to 50 units per minute.

Voltage: 220 V.

Year: ... |

|

|

|

Brand: Levapack

Automatic can seamer for aluminum, plastic and tin cans.

Manufacturer | model: LPE | Levapack.

Model: LPE - FLV 30.

Approximate capacity: up to 30 cans per minute.

Voltage: 220 V.

Year: 2018.

| |

|

|

Brand: Brapenta, Masipack, Metalgraf, Neife, SLP Indústria de Máquinas

Components: Siemens, WEG

Can filling system.

Line for filling powdered products in cans, jars and bottles.

The line worked with 400 g cans and a taller 510 g can.

Depending on the density of the product, it can fill up to 600 grams.

- Dosing filling machine for j... |

|

|

|

Brand: BBULL TECHNOLOGY, Zegla

Complete filling line for cans of juices and still drinks.

For Hot Fill cans with nitrogen application.

Manufacturer | brand: Zegla.

Year: 2010 / 2011.

Approximate filling capacity: up to 6000 cans / hour.

Line composed of:

- Depall... |

|

|

|

Brand: Dixie Canner, Vinox

Brewery factory with tri-block kitchen.

Complete line for beer and draft beer production.

Approximate capacity: up to 15,000 liters.

Year of manufacture: 2018.

For all types of beers and draft beer.

An earth filter was added to optimiz... |

|

|

|

Brand: Toledo

Can filling line for powder products.

It was used to fill cans of powdered milk.

Approximate capacity: from 80 to 100 cans / minute.

For cans with a diameter of 198 mm.

For more information, get in touch.

Line composed of:

- Depalat... |

|

|

|

Brand: Alfa Laval, Endress Hauser, Endress+Hauser, SMAR, Tetralon, Valmicro

Reactor tank for processing food products, among others.

Composed of:

- 2 Mixing reactors with an approximate capacity of 1140 liters.

- 2 Reactor agitators, SEW manufacturer, with a 12.5 HP motor.

- 2 Tetralon lobe pumps, Tetralon manufa... |

|

|

|

Brand: Alfa Laval, APV, Endress Hauser, Endress+Hauser, Loma Systems, NASH, SMAR

Automated system for preserving the integrity of products with chunks.

Set of industrial equipment for food processing, specifically designed to produce items with solid chunks that do not break down during the process.

Approximate capacity: 45... |

|

|

|

It manufactures a production line for zipper sliders.

The zipper slider factory is responsible for producing sliders, which are the metal parts responsible for opening and closing the zipper when they are slid over the teeth.

Slider Production ... |

|

|

|

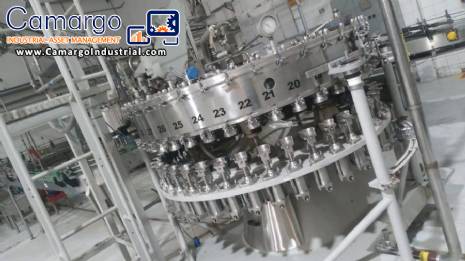

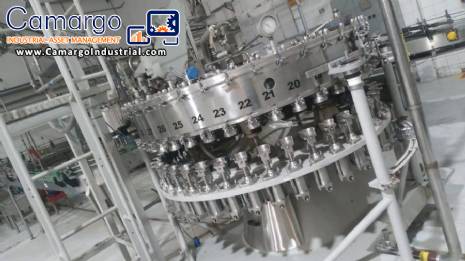

Brand: Metalgraf

Components: Siemens

4-head seamer for metal cans.

Manufacturer/brand: Metalgraf.

Year: 1994.

With manual.

Approximate capacity: 90 cans per minute.

With panel.

Components: Siemens frequency inverter.

WEG motor.... |

|

|

|

Brand: Dixie Canner

Sealer seamer for cans.

Manufacturer: Dixie Double Seamer.

Model: 25D - 600.

Approximate capacity: 500 cans / hour.

Year: 2010.

For various sizes of cans.

It was used for seaming energy drink cans.... |

|

|

|

Brand: Angelus, Grown Simplimatic, Pakmatic, Solbern

Complete line for can depalatization, rinser, filling, can rewriter, conveyor, chiller tunnel, baler, palletizer and strech wrapper.

More information get in touch.

Production: 42,000 u / h.

Depalletizer.

Brand: Grown Simplimatic.

Washe... |

|

|

|

Cravadeira manual for cans... |

|

|

|

Brand: Anacom, Drill Machine, Franho, Galax, Index, Invicta, Morand, Morganite, Nardini, Rocco, ROMI, Tecnoavance

Components: Fagor, Fanuc, Siemens

Metallurgical industry for the manufacture of wheels (vehicle hoops).

Date of foundation: 1987.

The company has as an activity the manufacture of sports wheels for motorcycles and mopeds, being alloy wheels and hubs for wheels.

The company i... |

|

|

|

|

Visitation: Schedule date for visitation and check equipment availability. Merely illustrative images.

|

|

|

| |

|

|

Camargo Industrial acts exclusively as an advertising platform. All information, photos, descriptions, conditions, and equipment compliance are the sole responsibility of the advertisers, and it is up to the buyers to verify their accuracy before purchasing. Camargo Industrial does not guarantee the accuracy, completeness, legal and technical availability of the advertised equipment.

Workplace safety with machinery: The platform does not perform inspections or certifications. The suitability of equipment to standards is the responsibility of sellers and buyers.

|

|

| |

|